Post by : Bianca Suleiman

The Western initiative to establish a self-sufficient rare earth magnet sector is confronting significant hurdles: the scarcity of heavy rare earth elements. While MP Materials, supported by the U.S., is progressing in domestic magnet manufacturing, crucial components such as dysprosium and terbium are still largely dependent on China.

MP Materials, with its Mountain Pass mine in California, has increased light rare earth production by 51% this quarter. However, the mine yields only minimal amounts of heavy elements, which are essential for magnets that sustain power at elevated temperatures, particularly in applications such as electric vehicle motors and wind turbines.

To mitigate this shortage, MP and other Western enterprises are scouting for international supplies—ranging from Brazil and Malaysia to parts of Africa. Additionally, Apple’s commitment to recycling heavy rare earths through a $500 million partnership with MP demonstrates a strategic move. Despite these initiatives, projections indicate the West will still rely on China for 91% of its heavy rare earth needs by 2030, a slight improvement from 99% anticipated in 2024.

The high costs and restricted availability of heavy rare earths outside China are apparent in the market. For instance, dysprosium oxide sells at $900 per kg in Rotterdam, which is over three times the price of $255 per kg in China. This situation has compelled companies like Germany’s Vacuumschmelze to seek raw materials from Canada and Brazil for their operations in the U.S.

Despite hopeful new ventures, including Lynas Rare Earths’ processing facility in Malaysia and Iluka Resources’ refinery in Western Australia, substantial heavy rare earth production outside China remains several years away from satisfying demand. According to CRU, a global shortage of 2,920 tons of dysprosium and terbium oxides is expected by 2035, highlighting the significant gap between supply and escalating industrial needs.

Environmental issues further complicate matters. The extraction of heavy rare earths from ionic clay deposits often involves chemical methods that pose risks to local ecosystems, while the presence of radioactive elements in monazite ores necessitates careful handling and disposal. These challenges contribute to the slow and expensive scale-up of production outside of China.

While some firms are exploring magnet production that minimizes or completely forgoes heavy rare earths, their use in high-performance electric vehicle motors remains restricted. Without adequate access to dysprosium and terbium, the quest for large-scale Western magnet production continues to face significant obstacles.

As the race to diminish reliance on China’s rare earth supply intensifies, it is evident that the “heavies” pose one of the most formidable challenges for the West.

Kazakhstan Boosts Oil Supply as US Winter Storm Disrupts Production

Oil prices inch down as Kazakhstan's oilfield ramps up production, countered by severe disruptions f

Return of Officer's Remains in Gaza May Open Rafah Crossing

Israel confirms Ran Gvili's remains identification, paving the way for the Rafah border crossing's p

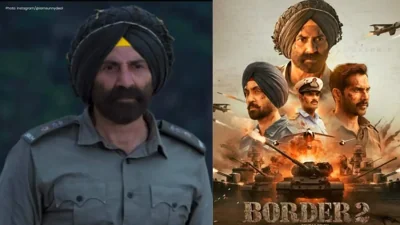

Border 2 Achieves ₹250 Crore Globally in Just 4 Days: Sunny Deol Shines

Sunny Deol's Border 2 crosses ₹250 crore in 4 days, marking a significant breakthrough in global box

Delay in Jana Nayagan Release as Madras HC Bars Censorship Clearance

The Madras High Court halts the approval of Jana Nayagan's censor certificate, postponing its releas

Tragedy Strikes as MV Trisha Kerstin 3 Accident Leaves 316 Rescued

The MV Trisha Kerstin 3 met an unfortunate fate near Jolo, with 316 passengers rescued. The governme

Aryna Sabalenka Advances to Semi-Finals, Targeting Another Grand Slam Title

Top seed Aryna Sabalenka triumphed over Jovic and now faces Gauff or Svitolina in the semi-finals as