Post by : Sami Jeet

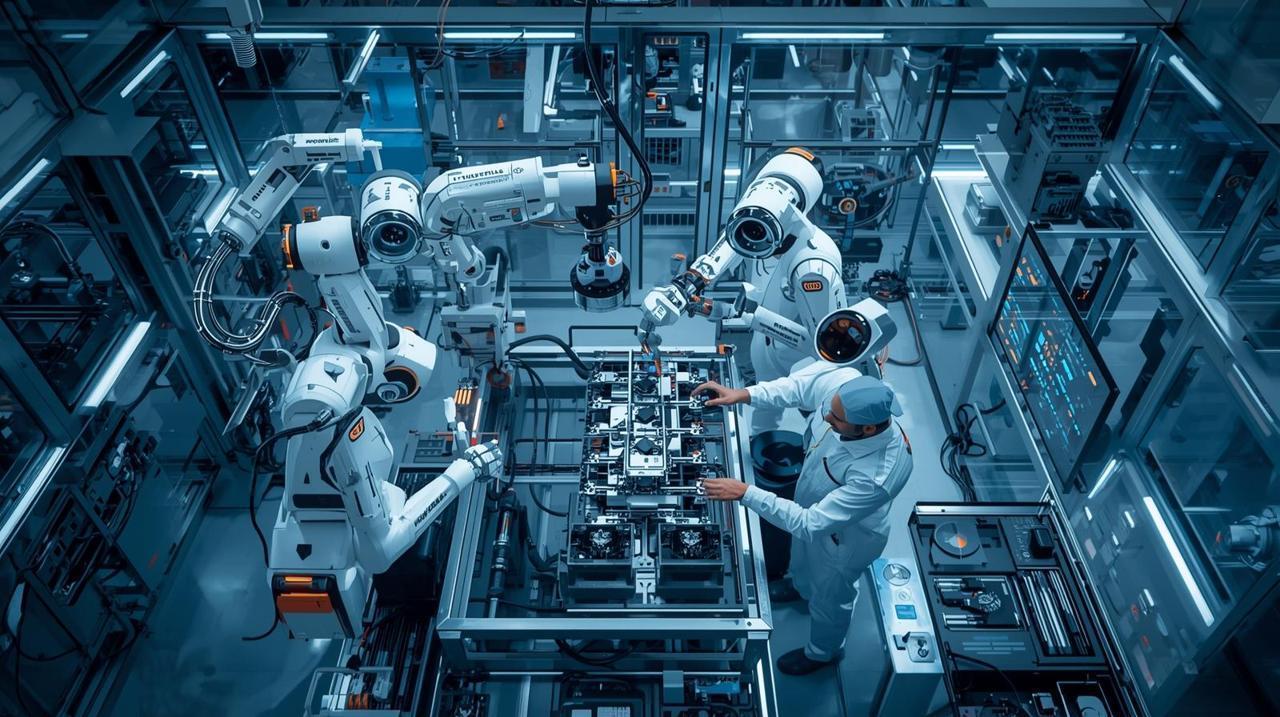

Manufacturing is undergoing a strategic shift as artificial intelligence (AI) and robotics converge to create more connected, efficient production environments. What were once labour-heavy workshops are evolving into systems where data, machines and people interact in real time to deliver higher productivity and quality.

From automated production and predictive upkeep to collaborative workstations, these technologies are not merely incremental improvements—they are redefining industrial operations and competitive advantage.

Where previous generations sought gains through scale, today’s manufacturers pursue performance through intelligence. The adoption of machine learning, AI-driven analytics and advanced robotics underpins what is commonly called Industry 4.0, a framework linking equipment, personnel and data streams.

Industrial robots have evolved beyond fixed, single-purpose machines. Modern designs prioritise flexibility, safety and adaptability, enabling more varied interactions with human teams.

Collaborative robots, or cobots, are engineered to share workspaces with people without the need for extensive guarding.

Cobots perform precision tasks such as fine assembly, inspection and packing.

They are often simple to reprogram for different operations.

Deployment of cobots can reduce defects and speed up throughput.

Manufacturers like ABB, KUKA and Universal Robots have driven cobot affordability and usability, widening access for small and medium-sized enterprises.

AMRs equipped with sensors and computer vision are changing material handling. These mobile systems map floors, move inventory and avoid obstacles autonomously, streamlining logistics inside large facilities.

By taking on routine transport duties, AMRs can improve safety and throughput, a capability embraced by major fulfilment centres such as those operated by Amazon.

Robots act as the hands of modern factories; AI provides the decision-making capability. Through analysis of production telemetry, AI systems identify inefficiencies, forecast failures and optimise output.

Predictive maintenance leverages sensor data and algorithms to flag equipment issues ahead of failure, enabling scheduled interventions rather than reactive repairs.

It helps limit costly downtime.

Maintenance can be planned more effectively.

Machines tend to enjoy longer service lives.

Research from McKinsey indicates that AI-driven predictive maintenance can trim maintenance expenses by up to 25% and reduce unexpected breakdowns by as much as 70%.

AI-infused computer vision systems enhance quality assurance by spotting defects imperceptible to human inspectors, helping manufacturers meet strict tolerances.

Sectors including semiconductors, automotive and pharmaceuticals rely on these systems to uphold standards and avert costly recalls.

AI also delivers end-to-end visibility across supply networks. Advanced models enable firms to:

Forecast demand with greater accuracy.

Automate inventory adjustments.

Plan more efficient distribution routes.

Such capabilities reduce waste, improve delivery performance and strengthen the resilience of global supply chains.

Automation is expanding, yet human expertise remains central. The prevailing model emphasises augmentation over substitution, allocating hazardous or repetitive tasks to machines while people focus on oversight, creativity and troubleshooting.

Firms that invest in training for collaborative work with intelligent systems report higher productivity and faster innovation, aided by simulation-based and AI-enhanced upskilling initiatives.

Modern production sites generate vast volumes of data from sensors and control systems. AI converts those streams into actionable intelligence, supporting near real-time operational choices.

Connected factories use insights to:

Automatically adapt production schedules.

Pinpoint throughput bottlenecks.

Lower energy consumption.

As datasets grow, systems become increasingly adaptive, creating a feedback loop of continual improvement.

The marriage of additive manufacturing and AI is enabling optimised component designs that are lighter, stronger and cheaper to produce.

Industries such as aerospace, automotive and healthcare exploit this pairing to make bespoke parts more rapidly and with minimal material waste.

AI and robotics can also reduce environmental impact. Intelligent factories:

Cut energy waste through continuous monitoring.

Use materials more precisely via robotic control.

Lower emissions by streamlining logistics.

For instance, Siemens applies AI-driven energy management across operations to shrink carbon footprints, demonstrating how efficiency and sustainability can align.

Despite advances, adoption faces obstacles:

Large upfront investments that can deter smaller manufacturers.

Greater cybersecurity exposure from interlinked systems.

Risks of workforce displacement and social impact.

Shortage of specialised skills in AI, data science and robotic maintenance.

Addressing these issues requires coordinated action—government support, public-private partnerships and expanded AI literacy programmes to broaden access and capability.

Leaders in the smart-manufacturing transition include Germany, Japan, South Korea and China, while nations such as India and the UAE are promoting Industry 4.0 policies to attract investment.

Corporations like Tesla, Foxconn and Bosch illustrate how automation and AI can scale output without sacrificing quality. The global market for smart manufacturing is expected to top $800 billion by 2030, driven by further integration of AI and automation technologies.

The long-term trajectory points toward increasingly autonomous facilities where AI orchestrates production flows with minimal manual intervention.

Envision a plant where:

Systems predict demand and adapt production in real time.

Robots perform assembly, inspection and packaging continuously.

AI negotiates supply and delivery terms dynamically.

Advances in AI, robotics, IoT and 5G make this scenario increasingly attainable.

The integration of AI and robotics is transforming manufacturing into a data-driven, safer and more efficient sector. While cost, security and workforce issues persist, the gains in productivity, quality and sustainability are substantial.

As smart factories spread and technologies mature, AI-powered manufacturing will not only produce goods more effectively but will also reshape industrial strategy at a global scale.

The next industrial era is unfolding—and it is defined by intelligence, automation and systemic resilience.

Kazakhstan Boosts Oil Supply as US Winter Storm Disrupts Production

Oil prices inch down as Kazakhstan's oilfield ramps up production, countered by severe disruptions f

Return of Officer's Remains in Gaza May Open Rafah Crossing

Israel confirms Ran Gvili's remains identification, paving the way for the Rafah border crossing's p

Border 2 Achieves ₹250 Crore Globally in Just 4 Days: Sunny Deol Shines

Sunny Deol's Border 2 crosses ₹250 crore in 4 days, marking a significant breakthrough in global box

Delay in Jana Nayagan Release as Madras HC Bars Censorship Clearance

The Madras High Court halts the approval of Jana Nayagan's censor certificate, postponing its releas

Tragedy Strikes as MV Trisha Kerstin 3 Accident Leaves 316 Rescued

The MV Trisha Kerstin 3 met an unfortunate fate near Jolo, with 316 passengers rescued. The governme

Aryna Sabalenka Advances to Semi-Finals, Targeting Another Grand Slam Title

Top seed Aryna Sabalenka triumphed over Jovic and now faces Gauff or Svitolina in the semi-finals as