Post by : Anees Nasser

Initially, foldable phones and tablets captivated users with their novel designs, yet they often came with a frustrating crease where the screen folded. This crease was more than just a blemish; it revealed fundamental engineering challenges. The flexible OLED stacks, protective cover layers, and hinge mechanisms needed to bend repeatedly without compromising the display or separating conductive elements.

By 2026, manufacturers have made significant strides in reducing or completely eliminating that crease. This achievement is not merely due to a single innovation but rather a comprehensive solution involving new substrate materials, redesigned hinge mechanics, distributed circuitry, and enhanced manufacturing practices. Observing this evolution illustrates how various fields came together to address a complex reliability challenge at the core of foldable user experience.

The first flexible OLEDs relied on polyimide and thin glass that could endure bending but were prone to micro-fractures along the fold. The next generation shifted to engineered copolymers and composite films that exhibit both high modulus and significant elongation at the breaking point. These materials can withstand numerous fold cycles while maintaining strong adhesion of conductive traces and emitter integrity.

Key features engineers aimed for included low hysteresis, excellent creep resistance, and thermal stability during display manufacturing processes that involve high-temperature deposition.

By 2026, “ultra-thin glass” (UTG) becomes integral to many creaseless designs. Produced in sub-100 µm sizes, the UTG is chemically reinforced to prevent micro-fractures. The innovation lies in combining the UTG with polymer interlayers, allowing small glass sections to offer scratch resistance while the polymer matrix helps distribute bending stress. This hybrid approach maintains the desirable rigidity of glass while allowing the display to flex seamlessly.

Creases often arose due to stress at material junctions. Engineers have incorporated graded adhesives—layers specifically designed to transition from stiff to flexible—to alleviate strain in the folding area. These adhesives bond robustly to both glass and polymer layers while withstanding temperature variations and humidity, preventing issues that used to exacerbate creases.

Reducing the thickness of various layers decreases the stress on bending. As of 2026, OLED emitter layers and encapsulation films have been optimized for flexibility, using advanced deposition techniques like low-temperature atomic layer deposition to create even thin films that retain excellent electrical performance while withstanding bending.

Rather than relying on a continuous backplane, many modern designs feature segmented active matrices positioned near the fold. Splitting the display’s driving electronics minimizes stress on any one area, ensuring no single high-stress conductor crosses the hinge. Floating “islands” of circuitry are interconnected using flexible interposers, which contribute to reducing strain and avoiding permanent distortions.

To accommodate minor circuit failures (such as open circuits that would darken pixels), manufacturers have begun implementing redundant routing systems. Duplicated traces and localized drivers ensure continued functionality even if one trace experiences wear. Although this increases complexity and cost, it significantly enhances durability and eliminates minor imperfections that could appear as creases.

Improperly designed hinges lead to excessive bending or uneven compressing of the display. Creaseless systems now utilize complex hinge geometries that distribute bending over a gentler radius, allowing the display substrate to slide slightly. Some incorporate dual-shaft linkages regulated by internal cams; others use specially crafted torsion springs for a consistent curvature during folding.

Shifting the neutral axis—the layer experiencing minimal strain during bending—is crucial. Engineers have adjusted this axis away from vital layers via internal shims and localized stiffness control. Innovations such as micro-sliding minimize shear forces during folding, controlling the fold arc and drastically reducing visible creasing.

Premium devices now include miniature actuators that facilitate smooth transitions during folding and unfolding, preventing sharp bends. These microelectromechanical systems (MEMS) are integrated into hinge assemblies, providing near-zero crease visibility in high-end models through real-time curvature adjustments.

Traditional metal traces are prone to cracking under frequent bending. The 2026 advancements include stretchable conductors utilizing silver nanowires embedded in elastic matrices, ensuring conductivity during repeated folding and minimizing tiny electrical inconsistencies that can be mistaken for creases.

Bending alters thermal conduction pathways. Areas prone to creasing used to suffer overheating during high brightness levels, which increased material fatigue. Modern displays now come equipped with thermal dispersers and localized power management solutions, enhancing durability and maintaining even brightness across folds.

Achieving reliable creaseless performance required significant advancements in manufacturing precision. Laser patterning and dry etching create micro-scale features with minimal mechanical stress, yielding consistent ultra-thin films vital for avoiding fold lines.

Quality assurance procedures now include automated fold-unfold cycles under thermal and humidity exposure for every display. Advanced machine vision systems can detect minute inconsistencies that human inspectors might overlook, leading to early identification of potential displays that could show visible creases.

Cooperation among suppliers of polymers, glass, adhesives, and hinge components has led to standardized practices that ensure matching thermal expansion rates and mechanical properties. This has mitigated previous mismatches that caused micro-delamination and surface feature issues.

Creaseless stacks are more costly to design and fabricate. The added complexity of segmentation, redundancy, and specialized adhesives raises bills of materials. Additionally, hybrid combinations of glass and polymer surfaces pose challenges for repair, complicating ongoing discussions about the right to repair.

While minimizing fold ridges, some creaseless designs necessitate additional internal structures—micro-sliders, segmented backplanes, and thermal spreaders—that may slightly increase thickness or weight. Engineers must carefully balance these factors against user preferences; most users prefer slight weight increases over visible creases.

Laboratory tests are controlled; real-world use involves factors such as temperature extremes, debris, and pressure from pockets. Studies in 2026 indicate remarkable advancements, yet challenges remain—rough folds or unintentional over-compression may still cause localized wear.

The most immediate benefit for users is a smooth touch experience across the fold and an uninterrupted image across the display. Applications that extend across the fold operate more fluidly, allowing for richer user interactions and multitasking opportunities.

With the crease largely resolved, manufacturers are reimagining form factors: larger pocket-sized tablets, rollable microdevices, and hybrid laptops that can fold flat without unsightly ridges. This evolution has inspired new application designs that leverage the seamless presentation.

Research in 2026 is advancing towards self-healing adhesives capable of microscopically repairing delaminations and dynamically adjustable optical layers to conceal surface irregularities. These innovations could potentially render any residual crease invisible to the human eye.

For true device flexibility, foldable power sources and sensing layers are essential. Future innovations will likely lead to foldable batteries featuring segmented cells and printed sensors in the fold area, enhancing gesture recognition and haptic feedback for a seamless display experience.

The creaseless foldable displays anticipated in 2026 arise from ongoing innovations across materials science, mechanical design, thin-film electronics, and manufacturing processes. It is not the result of a miracle material but rather a holistic approach—featuring graded interfaces, segmented electronics, advanced hinge designs, and refined manufacturing techniques—that has turned what was once seen as a limitation into a mere design footnote.

For consumers, the outcome is straightforward: foldables that behave like an uninterrupted screen. Engineers, meanwhile, learn that intricate user challenges can often be addressed by integrating small advancements across numerous layers, rather than depending solely on grand innovations. The era of creaseless foldables is a compelling demonstration of this engineering principle at work.

Disclaimer: This article outlines engineering trends and technical strategies widely regarded within the display and device industries as of 2026. Actual implementations may vary by manufacturer, with device behavior being contingent upon design choices, usage patterns, and environmental factors.

Kazakhstan Boosts Oil Supply as US Winter Storm Disrupts Production

Oil prices inch down as Kazakhstan's oilfield ramps up production, countered by severe disruptions f

Return of Officer's Remains in Gaza May Open Rafah Crossing

Israel confirms Ran Gvili's remains identification, paving the way for the Rafah border crossing's p

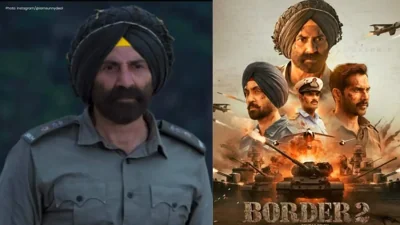

Border 2 Achieves ₹250 Crore Globally in Just 4 Days: Sunny Deol Shines

Sunny Deol's Border 2 crosses ₹250 crore in 4 days, marking a significant breakthrough in global box

Delay in Jana Nayagan Release as Madras HC Bars Censorship Clearance

The Madras High Court halts the approval of Jana Nayagan's censor certificate, postponing its releas

Tragedy Strikes as MV Trisha Kerstin 3 Accident Leaves 316 Rescued

The MV Trisha Kerstin 3 met an unfortunate fate near Jolo, with 316 passengers rescued. The governme

Aryna Sabalenka Advances to Semi-Finals, Targeting Another Grand Slam Title

Top seed Aryna Sabalenka triumphed over Jovic and now faces Gauff or Svitolina in the semi-finals as